What is a Virtual Power Plant (VPP)?

Definition

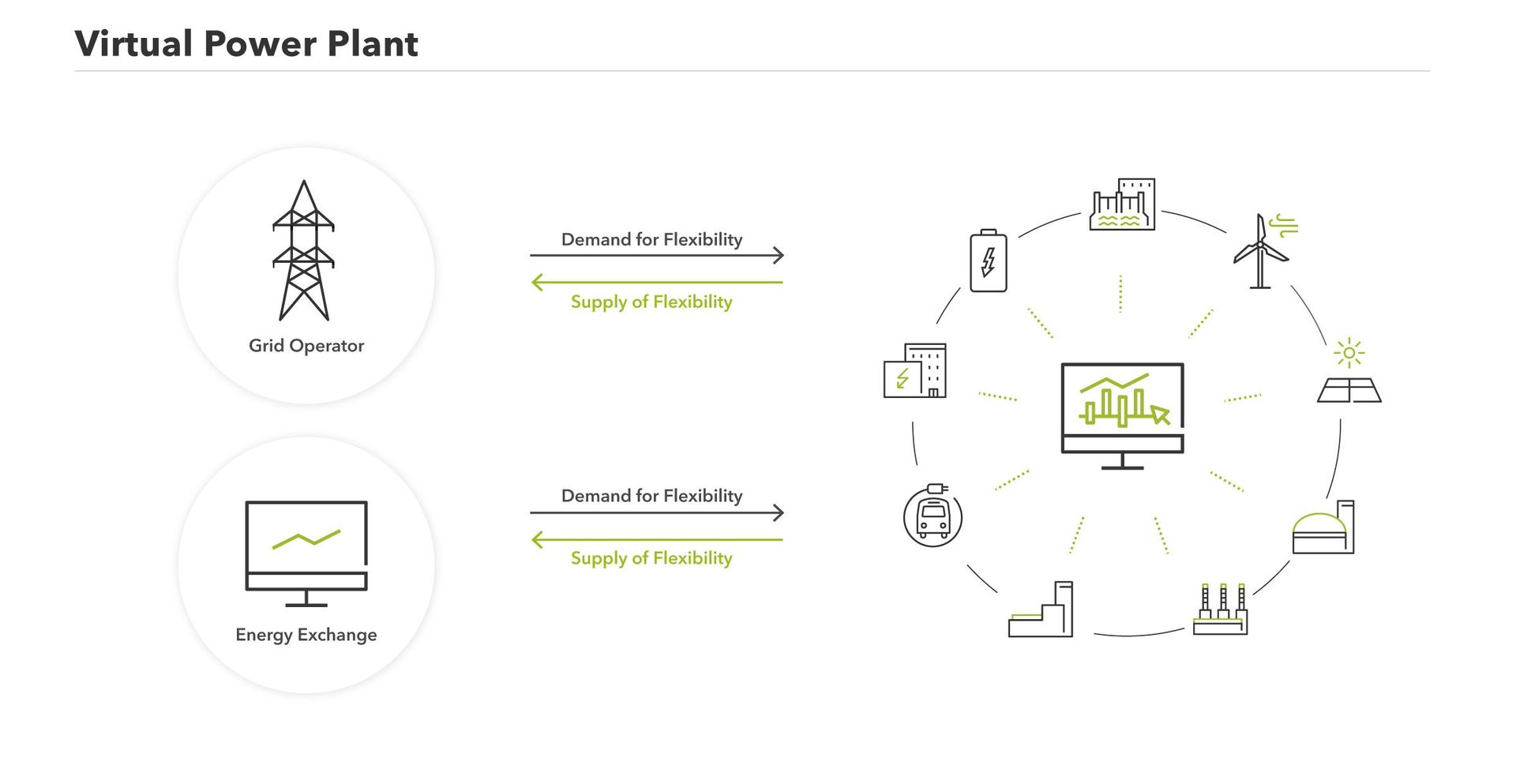

A Virtual Power Plant is a pooled set of decentralized units in a power network. Virtual Power Plants are operated by a common, centralized control system. The networked units can be power producers (such as biogas, wind, solar, CHP, or hydro power plants), power consumers, power storage units, and power-to-X plants (power-to-gas, power-to-heat). The Virtual Power Plant’s purpose is to collectively forecast, dispatch, and trade the power and the flexibility of the aggregated assets. Any decentralized unit that produces, consumes, or stores electricity for the power exchanges can be part of a Virtual Power Plant. The cluster of individual assets is operated by a central control system. In addition to operating each individual asset in the Virtual Power Plant, the system uses a special algorithm to adjust to grid conditions and control reserve commands from transmission system operators – just like larger, conventional power plant (hence its name...). When it comes to trading electricity, the Virtual Power Plant can react quickly and efficiently to price signals from the power exchanges and adjust operations accordingly.

Table of Contents

- From individual assets to a power plant swarm

- Collective intelligence of decentralized units

- Virtual Power Plants create flexibility in power markets

- The price of electricity fluctuates - and the amount of available power is not always the same

- Virtual Power Plant interface and network connection

- Control reserve from Virtual Power Plants

- Power consumers in Virtual Power Plants

- Private homes will have to wait for smart meters

- Virtual Power Plants digitize the energy sector

From individual assets to a power plant swarm

A single unit is not going to make the difference in the energy transition. Establishing a real foothold in the power market means renewable energy producers need to join together as a larger group. The initial concepts for a Virtual Power Plant date back to the end of the 1990s, a time that saw a general liberalization of the power market. Back then, these concepts were mostly theoretical: existing computer and network technology, and the prevailing regulatory conditions, were not conducive for projects to take shape at the necessary scale for economic and systemic development of a Virtual Power Plant.

But by around 2010, two events occurred that helped make the Virtual Power Plant a reality. First, computer technology had improved significantly, paving the way for a readily-available, high-performance control system that operates in real time. Second, the German government declared the country’s exit from nuclear power, announced new structures for the energy market, and added important amendments to the Renewable Energy Act. These changes provided the legal and economic foundation for Germany’s energy transition: The Virtual Power Plant's time had arrived.

Collective intelligence of decentralized units

On the power markets, Virtual Power Plants play a similar role as large, conventional power plants. The total capacity of a Virtual Power Plant is often equal to one or several nuclear power plants. Since Virtual Power Plants consist of networked assets producing power from renewable energies, the total capacity changes constantly. If the sun isn't shining or the wind isn’t bowing, for example, wind and solar assets contribute less to the Virtual Power Plant. Beyond a theoretically endless mix of power producers, the collection of assets can also accommodate power consumers, power storage units, and power-to-x assets, including as power-to-gas (P2G) or power-to-heat (P2H).

It is important that a variety of energy sources are used to power producing units in a Virtual Power Plant to avoid an uneven power balance. The grid has a limited storage capacity, meaning the amount of power that can be fed into the grid is limited (within a certain tolerance) by how much can be simultaneously generated and consumed. Therefore, a Virtual Power Plant’s portfolio contains flexible power producers – like biogas and hydro (hydroelectric plants and pumped-storage plants) – and flexible power consumers, storage units, and power-to-x units, in addition to volatile producers like wind and solar. The flexible assets in a VPP can compensate for variations in power feed-in caused by clouds or lack of wind – in both positive and negative directions.

Virtual Power Plants create flexibility in power markets

The quick and versatile ability to balance the grid, also known as flexibility, is one of the Virtual Power Plant’s greatest strengths and the most significant difference compared to conventional power plants. By quickly adapting to the existing supply of power on the grid, Virtual Power Plants can utilize the aggregated power to react to changes in the electricity price on the exchange and execute trades. After all, the price of electricity fluctuates: Every day, the price changes 96 times in intra-day trading on power exchanges in Europe. A price spread of two and even three digits per megawatt hour is not unusual.

The price of electricity fluctuates - and the amount of available power is not always the same

Large power plants, which have a consistent output of several hundred megawatts, come up against their technical limitations relatively quickly. Picture a lignite power plant like a large container ship: there is a considerable “braking distance” before the plant’s turbines could be slowed enough to accommodate an increase in wind power availability during a storm. To prevent the grid from overloading, the climate-neutral wind power would be taken off the grid instead.

A Virtual Power Plant, however, would react to surplus of wind power by executing a simple command to reduce the output of, for instance, connected biogas and hydro plants. In the opposite case – a power shortage on the grid – the control system can increase biogas and hydro power plant power production or lower consumption by its connected consumers. The Virtual Power Plant directly balances fluctuation in power production and consumption in real time without straining the public grid. Commands that raise or lower feed-in amounts are executed by the control system using an API or remote-control units installed on each asset.

Virtual Power Plant interface and network connection

Within the Virtual Power Plant, transmitting commands and data between the highly-secure and redundantly-designed control system and the individual assets is conducted over a secure, tunneled data connection. These tunneled connections use the public communication infrastructure, but protocols are in place to separate information pertaining to the Virtual Power Plant from the public flow of data. This calls to mind buzzwords such as “the internet of things,” “industry 4.0,” and “M2M,” but it really refers to a specially secured and shielded mobile and hard-wired data connection.

The bidirectional connection between each asset and the Virtual Power Plant does more than simply facilitate the execution of commands. It also enables a permanent, real-time exchange of data pertaining to the capacity of the networked assets, and therefore the Virtual Power Plant as a whole. The data – which includes the reported feed-in capacity of wind and solar assets, consumption data, and storage capacity indicators – contributes to precise forecasting for power trading and operational scheduling of flexible power assets. Processing and evaluation of the data is mostly automated within the software architecture of the Virtual Power Plant. The software also takes on many of the tasks associated with initiating and executing trades on the power exchanges.

Control reserve from Virtual Power Plants

Flexible, renewable power producers such as biogas, hydro, cogeneration unit (CHP), and emergency power generators have an additional advantage: Not only are they able to reduce or cease power production when there is power surplus on the grid (negative control reserve), but they can feed-in additional power to the grid during electricity shortfalls (positive control reserve). For an asset to provide control reserve, it must have a capacity of at least one megawatt in most European markets (the minimum was previously five megawatts). To reach this threshold, several assets can be linked together in a Virtual Power Plant.

The cluster of assets collectively responds to control reserve orders by the Transmission System Operator, with profits shared among all asset operators. Power consumers can also provide negative control reserve: For example, an industrial plant connected to the Virtual Power Plant can receive a command to increase production and remove surplus power from the grid.

Power consumers in Virtual Power Plants

Thanks to the data collected in the Virtual Power Plant, commercial and industrial power consumers can profit from price signals coming from the power exchanges. Power consumption can be limited to times when electricity is readily-available on the market at a low price. If production operations are limited to low-price periods, a company can reduce power costs by up to a third.

If desired, the Virtual Power Plant can fully automate this optimization. The Virtual Power Plant’s control system sends commands to the company’s machine control room, but only to the extent that is possible and needed. In this case, however, a power meter with consumption metering must be installed. These are only available when annual consumption is expected to exceed 100,000 kWh.

Private homes will have to wait for smart meters

Private households do not reach this level of power consumption. Therefore, the integration of private homes into the Virtual Power Plant will have to wait until smart meters become the norm. Hopefully, smart meters will soon replace the old three-phase meters of the 1920s - a hundred years after they were introduced. With appliances such as heaters, ovens, washing machines, refrigerators, and hot water heaters intelligently-optimized to align with electricity prices, power consumption at home can become more cost-efficient.

Read more

Virtual Power Plants digitize the energy sector

The future is digital, and the energy sector is no exception. Like many areas of our society, the supply of electricity is undergoing a fundamental shift on a global scale. We are moving away from large, fossil-fueled power plants to smaller, decentralized units linked together through the constantly-expanding opportunities of digitalization.

Similar to hotel booking platforms that don't own hotels, or carsharing services that don’t own a fleet, Virtual Power Plants represent a democratic shift in power supply by shifting responsibility back to society: Virtual Power Plant operators don't own power plants; they simply optimize how each linked asset – still owned by a third party – is used. Today’s largest Virtual Power Plants have already far exceeded the installed capacity of the largest nuclear power plants, producing climate-neutral power from the cluster of assets and addressing challenges power markets will soon face. These include the increasing number of electric vehicles in the transport sector and the exponentially-growing number of network hubs and computing centers in response to digitalization – all of which require large amounts of electricity. This demand cannot be met while serving climate protection goals using conventional power supplies and/or a single source of power. By utilizing a wide-range of technologies and sources of energy, the decentralized and hybrid approach of a Virtual Power Plant is an important tool that will shape the energy landscape of the future.

Disclaimer: Next Kraftwerke does not take any responsibility for the completeness, accuracy and actuality of the information provided. This article is for information purposes only and does not replace individual legal advice.